Call 800-916-7873 in the USA

Text your questions to 269-601-4965

Canada shipping is flat rate at $25.00 USD. All prices in USD

Our mission is to rescue the victims of abusive high pressure sales by empowering them with information, rewarding them with savings and retaining them with customer service.

For our Canadian customers, there may be taxes and duties on your shipments now that our operations have moved to the USA. We apologize for any inconvenience.

Compare Electro Breeze V-Banks with Dynamic V8 Electronic Air Cleaner Filters

We are accepting orders once again!

There will be a 3-4 week delay in shipping and delivery, after your order is placed.

If you have any special instructions, please include them on your order at checkout.

Thank you for your patience and understanding!

Below, you will find a typical specification for Dynamic V8 electronic air cleaner filters. This specification was also used in a bid with Trane Commercial Air Conditioning for their installation of the Dynamic V8 filters. These are the same Dynamic V8 electronic air cleaner filters specified for the Daikin Air Conditioning package units. You will also see that the specification for this commercial air cleaner is written so that only the Dynamic V8 will meet the requirements. As you can see by comparing with the specifications further down, the Electro Breeze electronic air cleaner offers a better solution at a much better price.

Engineering spec for the Dynamic V8 electronic air cleeaner filters from Trane Commercial Air Conditioning:

- The air filtration systems shall be comprised of a bank of electronically active field polarized media air cleaners manufactured by Dynamic AQS or approved equal. The filtration units shall be constructed of non-ionizing, polarized-media electronic air cleaners, Model V8 MERV 15/13 rated per ASHRAE 52.2. The dual rating of the filters is based on a MERV 15 with power to the assembly and a MERV 13 performance on a loss of power. Any particulate captured will not drop off the media in a loss of power.

- The air cleaners shall have been tested to meet CSA Standard C22.2 No. 187-M19986 and UL Standard 867 for electrostatic air cleaners.

- The air cleaners shall have an active electrostatic field that polarizes a dielectric media. It shall not ionize airborne particles or produce ozone.

- Using the ASHRAE 52.2 protocol with no carbon in the loading dust, the air cleaners shall test at MERV 15. They shall have a clean static pressure drop of .42 in. w.g. and shall increase in resistance no more than .25 in. w.g. with a dust loading of 2,855 grams. Each air cleaner shall be capable of holding a total of 4,582 grams of dust at its final resistance of 1.4 in. w.g. per 24x24 module.

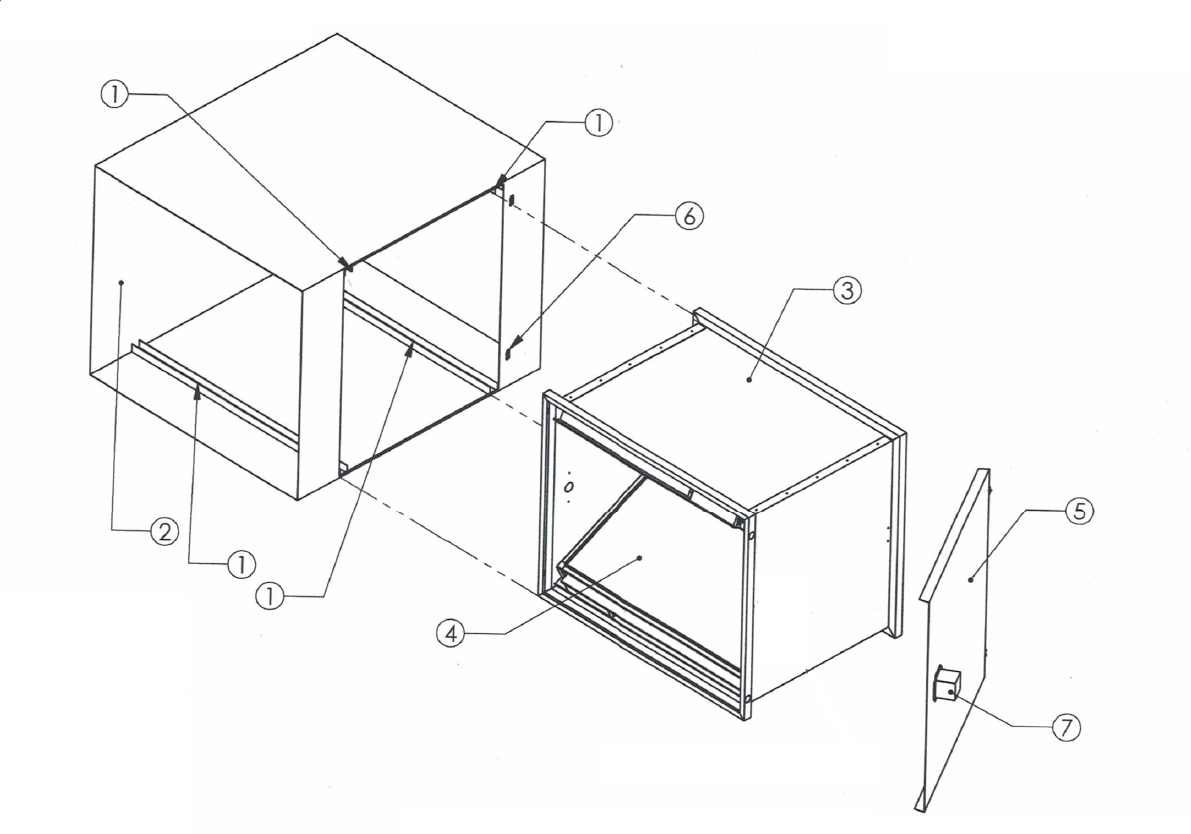

- The air cleaner modules shall consist of eight individual air cleaners. The construction of the air cleaner frame shall be aluminum and screens and side panels shall be galvanized steel. The air cleaner modules and each component thereof must have a positive seal where necessary to prevent bypass of air.

- Each air handling units air cleaner high voltage power heads shall require 24 volts AC input. The power heads must be fully potted and connected in parallel.

- Each air handling units filter unit shall require a single 120VAC power supply, one connection per air handling unit. The power supply must be a UL or CSA certified transformer, class 2 type, which shall permit one side of the secondary output, 24V, to be attached to electrical ground. A NEMA 1 panel rated for 5 amps will be provided.

- Each air cleaner shall have a disposable and recyclable media pad with a minimum class 2 fire rating. It shall have a positive seal in the overall filter assembly.

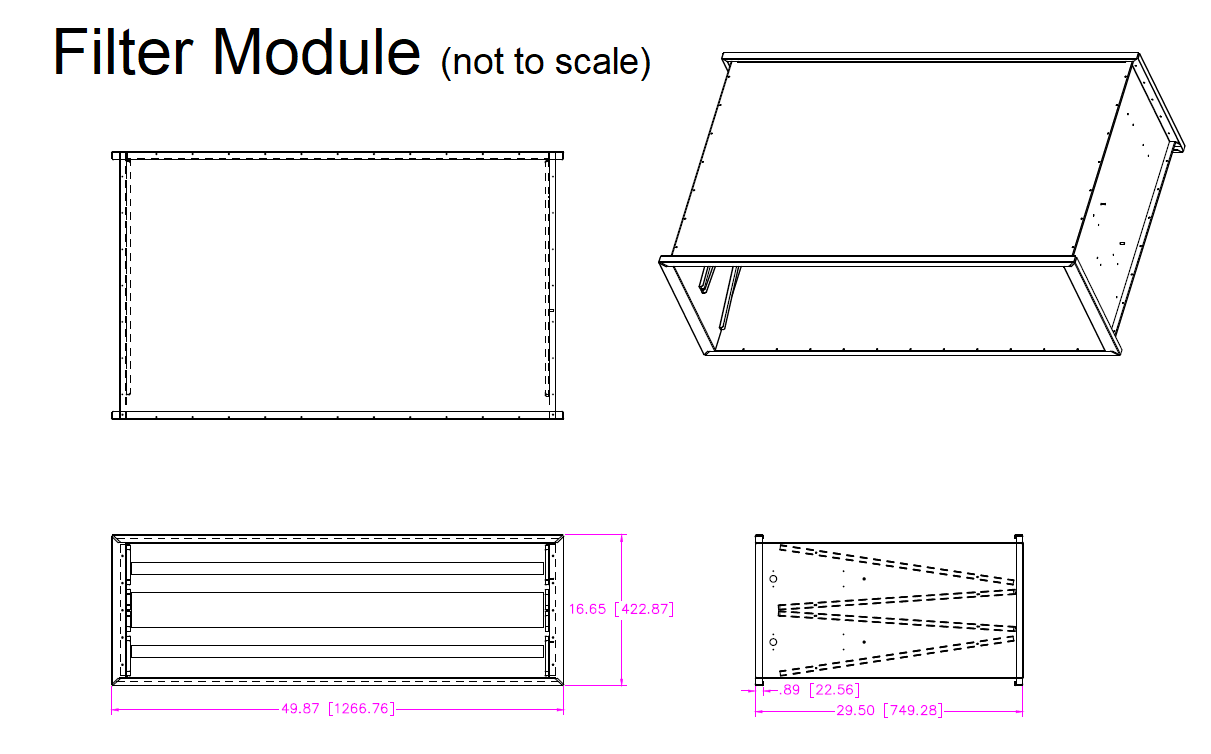

- The air cleaners will be arranged in a pre-fabricated module assembly comprised of eight separate air cleaners and galvanized metal sides and attachment flanges. Each V Bank module shall be nominal 12, 18 or 24 inches overall height, 26, 30, 34, 39, 43 or 48 inches overall width, and 29.5 inches overall depth. Final module sizing shall be by the air cleaner unit manufacturer and coordinated with the air handling units manufacturer so as to assure the filters will fit within the air handling unit allocated cabinet section, installed in the cabinet section at the air handling units manufacturers factory, and no additional modifications to the air handling unit and/or filter units will be required in the field.

Compare with the specifications of the Electro Breeze V-Bank commercial air filters:

- General: The V-Bank module filtration system shall be consist of eight 1-inch electronic air panels of electronically non-ionizing polarized media.

- Certification: The air cleaner shall have been tested and meet CSA Standard C22.2 and No 187-M19986 and UL standard 867 for electronic air cleaners.

- According to the Indoor Air Quality Procedures outlined in the ASHRAE Standard 62-2001, large buildings using the Electro Breeze air cleaner system may be able to cut their outside air requirements in half or even to a third.

- Operation: The air cleaner shall have an active electrostatic field that polarizes a dielectric collector cushion pad. It shall not ionize airborne particles or produce ozone.

- Performance: The air cleaner shall be able to remove 97.8% of the airborne particulates 0.3 micron and greater in a re-circulating system. Pressure drop across the air cleaner will be no more than 0.2”w.g. @ 300fpm.

- Construction: The V-Bank module cabinet shall be galvanized steel pre-fabricated module assembly. It shall be pre-fabricated to permit the assembly at the HVAC manufacturing plant. The air cleaner module shall consist of eight individual air cleaners. The construction of the air cleaner frame and screens shall be aluminum. A miniaturized electronic power supply (power head) shall be mounted in a channel on the frame of the air cleaner in a non-conductive housing. A folding glass fiber media that create two pads shall be placed between the outside grounded frame/screens and the center collector cushion carbon. The center collector cushion carbon or mesh shall carry the high DC voltage from the power head. The air cleaner frames shall be hinged so as to allow easy access to the media pad for replacement. Each 1-inch panel can be removed by sliding out each one for yearly maintenance or future full inspection.

- Electronics: The power heads shall be capable of converting 24VAC to the 7.2 kVDC and draw no more than two watts of power. The power head shall be insulated from the air cleaner frame and it shall transmit the 7.2 kVDC to the center collector cushion activated carbon of the media pad through a special copper filament. Each air cleaner shall have a “Power On” lamp and be equipped with a high-voltage resistor to de-energize the air cleaner when the power is shut off. The power heads will be connected in parallel so that if one fails, it will have no effect on the other power heads in the row.

- Power Supply: The 24VAC power supply must be a UL or CSA certified transformer, class “2” type, which shall permit one side of the secondary output (24V) to be attached to electrical ground.

- Air Cleaner Media: Replaceable air cleaner collector cushion pad shall be individual, disposable glass fiber “collector cushion”, which shall consist of a folded glass fiber pad that create two ply of fiber glass with a conductive center activated carbon or aluminum mesh. This conductive center carbon or mesh shall be permanently enclosed between the folded pad that makes two pieces of fiberglass and shall be disposed of when the collector cushion pad is changed. The glass fiber pad must be fabricated from a constant filament so that any shed fibers are not enhanced. The glass fiber must have a minimum of a class “2” fire rating.

- Each air cleaner shall have installed either a carbon or aluminum mesh core collector cushion pad.

Feel free to contact us with your questions or your request for quote at 800-916-7873 or email at john@airlifeone.com

Engineering specifications for all of the Electro Breeze air cleaner products can be found here.